Product Description

Rubber Expansion Joints Catalogue

RUGAVAL is expertise in manufacturing of Non-Metallic Expansion Joints Elastomer (rubber) have been specified for many years to accommodate movement in piping runs and insure efficient systems. Elastomer joints are widely used to provide efficient ways to relieve movement stresses, reduce noise, isolate vibration, compensate for misalignment. Elastomeric expansion joints are fabricated from synthetic elastomers and fabric, and are often reinforced with metal. When operating temperatures and pressures exceed 250°F and 200 psig, respectively, rubber should not usually be considered an alternative to metallic expansion joints.

Within these limits, elastomeric joints do offer advantages compared with metal joints, including:

1. Cycle Life - Many more cycles can be provided, and vibration fatigue is not a concern.

2. Stress Corrosion - They are chemically inert to most common corrosive elements.

3. Resistance to Abrasion and Erosion - They outlast metal joints in this respect.

4. Resistance to External Damage - With elastomer joints, accidental external blows do not cause damage.

5. Space Requirements - Metal joints require a considerably greater face-to-face dimensions.

6. Acoustical Impedance - They absorb a great deal of noise and vibration.

7. Light Weight - They are easy to handle and compact. 8. Low Cost - In general, they are less expensive than metal joints.

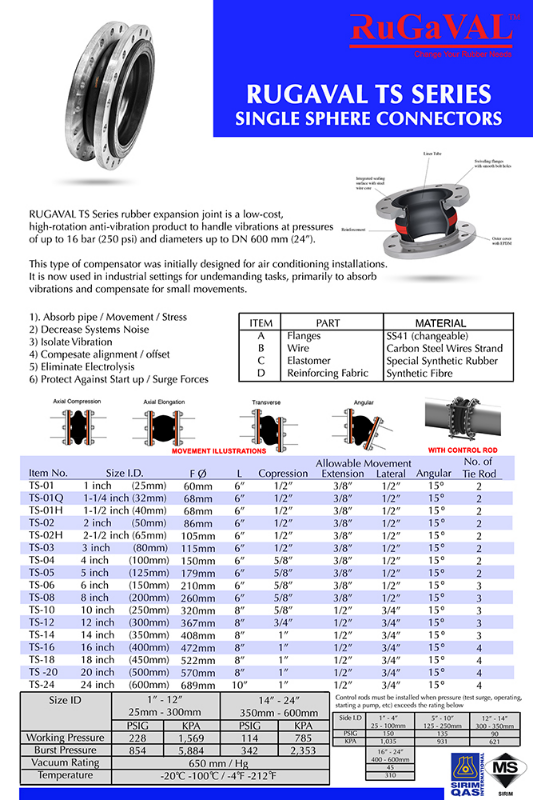

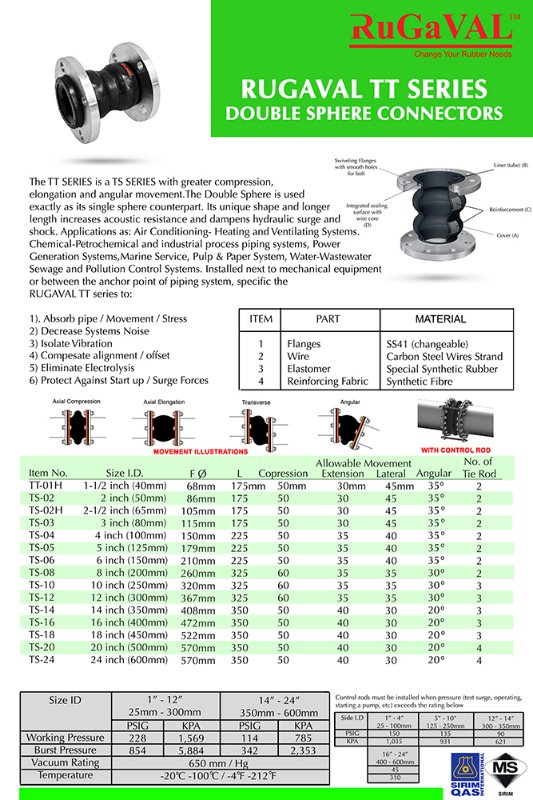

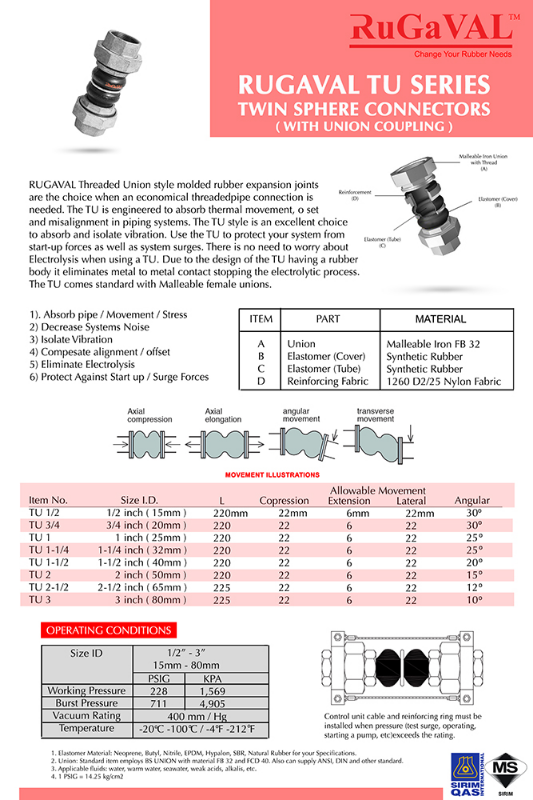

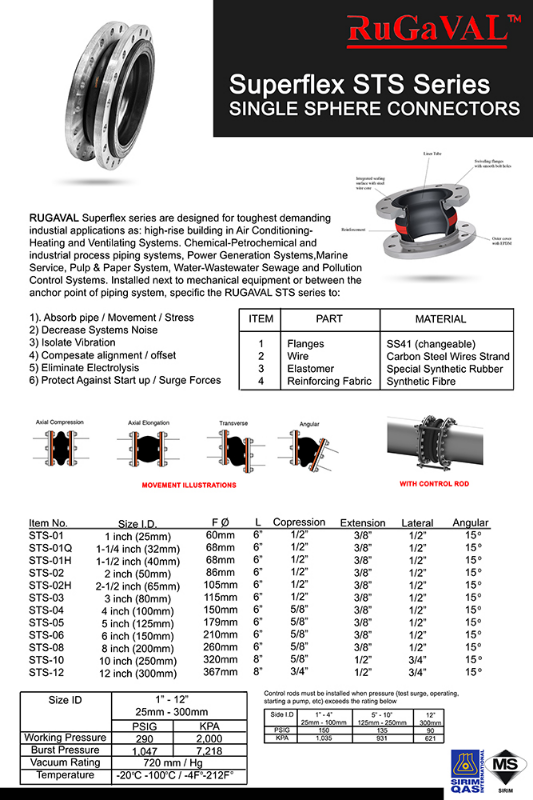

Below attachment copy is the range of catalogues for RUGAVAL Rubber Expansion Joint Series.

Contact Details

Rubber Expansion Joints Catalogue

| Supplier | : | Rugaval Rubber Sdn Bhd |

| : | rugavalrubber@gmail.com | |

| Phone | : | 60351918961 |

| Fax | : | 60351915961 |

| Location | : | Selangor, Malaysia |

Enquiry Box

Other Products

Loading...Please Wait.

Loading...Please Wait.