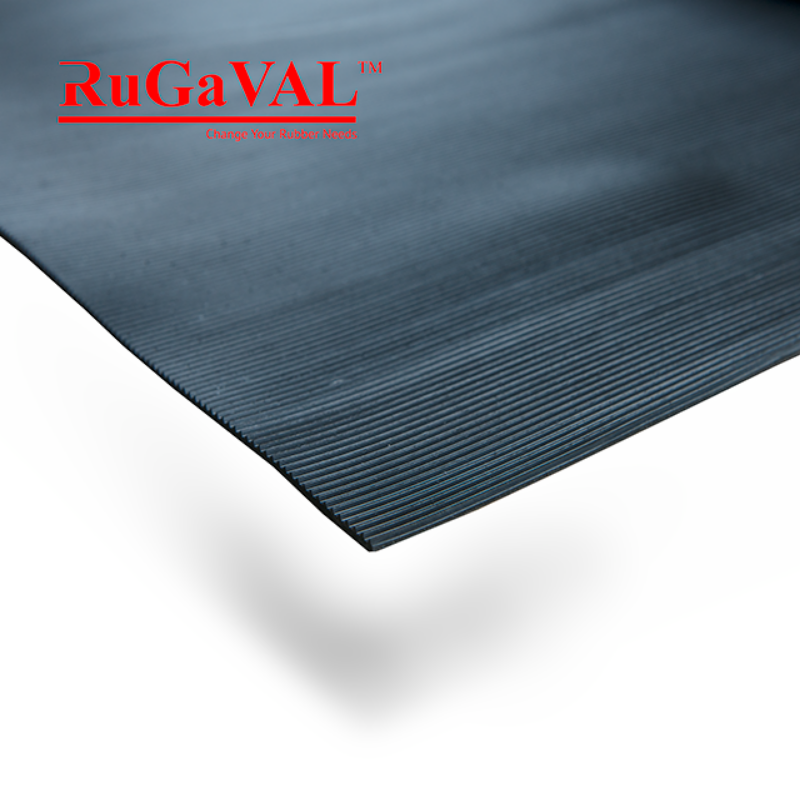

Product Description

Measurement Shore Hardness of Rubber | Shore Hardness | 60 Shore

Measurement Shore Hardness of Rubber

Methods for hardness measurement on elastomers are characterised by a set-up where indenters with various defined geometries are pressed under defined test forces into the surface of testing material. The hardness value represents the resistance of the material to the rigid indenter and is calculated from the indentation depth of the indenter in the to be tested material. The test methods IRHD and Shore are the most common methods used in the field of rubber hardness measurements. Appropriate hardness measuring instruments are spread world wide. A periodic verification has to be carried out to assure the accuracy of these measuring instruments. Direct and indirect verification methods are recommended to be used. For the indirect method rubber hardness reference blocks are used. This indirect verification method is especially appropriate for the daily check of hand held rubber hardness testers. On the other side the direct verification of test force, depth measuring system and indenter geometry is suited for the periodic calibration of rubber hardness testers. For the rubber hardness reference blocks their accurate hardness reference value and the long-term stability are the most important characteristics. In this paper the long-term behaviour of hardness of rubber blocks which at present are available on the market and are made by different producers is presented. For the measurements the Shore and IRHD hardness standard devices in the PTB have been used. In order to determine the relationship between hardness and time under the specified conditions a regression analysis of the obtained measurement results was carried out. The results of this analysis can be used for the improvement of quality assurance systems in the field of rubber hardness measurements.

HARDNESS OF RUBBER

Hardness of a material is generally defined as material's resistance to introduction of foreign bodies into its surface layers. At given temperature, it depends on material's physical properties, as well as on shape and properties of indentor. In fact, like moduli of elasticity, hardness may be envisioned as a measure of the material's stiffness. For crystals, e.g. metals, where indentation deformations are very small, hardness and elasticity moduli are nearly proportional to each other, especially if the ratio between elastic and plastic deformation work is constant. On the other hand, stiffness of amorphous polymers, like rubbers, is usually much lower and deformations in the vicinity of the indentor are large, highly in the nonlinear region. This, however, results in likewise courses of hardness and elasticity moduli, but not in exact proportionality between them. For practical purposes (products) rubber is used in crosslinked (vulcanized) state, i.e. in a form of three dimensional network made by intermolecular covalent linkages. These linkages thermally stabilize the raw rubber and make it highly elastic. Hardness increases with increasing linkage density. Besides, several other components that are normally added to rubber, such as reinforcing fillers (carbon black, silica) and softeners (oils), have a strong impact to its hardness. Whereas hardness increases with increasing content of fillers, it decreases with increasing amount of softeners. The latter are also the cause for rubber hardening with time. Though slowly, the softeners, which are not chemically bonded to rubber molecules, migrate by diffusion to rubber surface, where they evaporate. So, the gradual time loss of softeners causes rubber hardness to increase. Hardness of rubber also depends on temperature. By raising temperature the free volume of rubber increases and the effective potential barriers for molecular conformations decrease, making the network less stiff and thus causing drop of its hardness. Temperature dependence of rubber hardness is of Arrhenius type with the usual activation energies of a few kJ/mol. For measuring hardness of rubber the scales Shore A and IRHD are normally used, rarely the scale Shore D. Indenters’ shape and dimensions, as well as indentation force are standardised.

Contact Details

Measurement Shore Hardness of Rubber | Shore Hardness | 60 Shore

| Supplier | : | Rugaval Rubber Sdn Bhd |

| : | rugavalrubber@gmail.com | |

| Phone | : | 60351918961 |

| Fax | : | 60351915961 |

| Location | : | Selangor, Malaysia |

Enquiry Box

Other Products

Loading...Please Wait.

Loading...Please Wait.